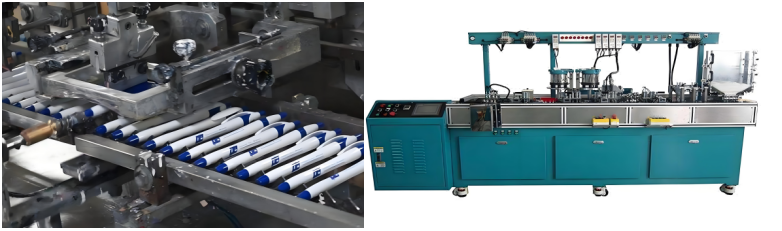

Fully Automatic Ball Pen Making Machine

"Fully automatic ballpoint pen assembly machine delivers high-speed production (3,000-8,000 units/hour) with intelligent PLC control, precision sensors, and modular design. It handles various pen types, ensuring minimal downtime and error rejection. CE/ISO certified, energy-efficient, and suitable for 24/7 operations. Reduces labor costs by up to 70%, ideal for large-scale manufacturing."

Fully Automatic Ball Pen Making Machine

Product Description

Main features:

This machine adopts the man-machine interface of the machine by PLC microcomputer and high precision sensor control and

detection, using inverter and encoder to make the machine running at high speed to ensure a stable and orderly work, this series

of models with JB industry standard design, by mechanical linkages, pneumatic auxiliary design concept, driving part adopts the

Germany IGUS mostly free of oil bearing, reached the JY education stationery industry standards, all electrical parts are imported

components, frame by phosphating surface spraying thermosetting plastic powder processing, makes the machine to adapt to any

environment from corrosion; The design of this series of models in line with the principle of energy saving,

improve productivity, and reduce the input of manpower, can effectively make users get higher economic benefits.

Ball-point pen making machine set automatically installed hot stamping, automatic feeding, automatic assembly, automatic

production to various agencies reflect clearly, reference for beginners and learning, and study the selection of standard equipment

Parameter:

1) equipment installation dimensions:

2) length: 4000 mm width: 1350 mm height: 1720 mm (mainly equipment actual) site required for

3) air supply:0.5mpa ~ 0.7mpa

4) power supply: general specification of AC 220V 380V equipment

How big does it take to build a pen machine factory?

Answer: make pen workshop area big, small all but, cannot under 50 square metre commonly. A pen production line covers an

area of about 20 square meters, plus at least 20 square meters for stacking, feeding and packaging of finished products. If the

production line above BE-YZ200 is purchased, or several production lines are put on at the same time, the plant area shall be

expanded correspondingly.

Introduction – Who We Are & What We Offer

B&E is a leading manufacturer of pen manufacturing machine Factory, specializing in custom solutions for all kind or pen .

We provide the whole pen production line such as ball pen barrel making machine,Ball pen barrel injection mould,pen assembly

machine,pen barrel labeling,package mahine,pen refiller , and more. All products are made from our reliabel professional team.

Whether for pen making machine, product packaging, or industrial equipment, we deliver cost-effective and the whole solutions

tailored to your specific needs.

Specification

working speed | 60-80pcs/min |

Work station: | 2up |

air | 5-6kgf/cm² |

Working type | Automatically |

Power supply | 220V/50HZ |

Detailed Images

Packing & Delivery

Business process

1. Inquiry-Customers can provide sample pictures or send samples to us, and we will prepare a specific quotation plan for you。

2. Confirm the price, leadtime, payment term etc

3. B&E Machine sales send the proform invoice with B&E Machine seal

4. Customer make the payment for deposit and send us bank receipt and offer test samples,The sample quantity is around 3,000 to 5,000 sets

5. Inform customer has got the deposit and start to production

6. Middle production- send photos to show the production line which you can see your products in. Confirm the estimated delivery time again

7. Clients make payment for balance and B&E Machine ship the goods. Also can accept payment term-Balance against B/L Copy Or L/C payment Term.

Inform the tracking number and check the status for clients.

8.Order can be say “finish” when you receive the goods and satisfy with them.

9. Feedback to Freedom about Quality , Service, Market Feedback & Suggestion. And we can do better.

Packing&Deliver

We take care of our machine packing and loading.Pen production machine with antrust process, make sure no rust due to ocean shipment.

Each package would be fixed stable inside container,make sure no damage or crash during whole shipment.We should take photos of loading,

and send to you for reference.

FAQ

Q1: Do you have reference project?

A1: We have reference project in most countries,If we get the permission of the customer who has brought the machines from us ,we can

tell you their contact imformation,you can go to vist their factory.

And you are always welcome to come to visit our company,and see the machine running in our factory,we can pick you up from the station

near our city.Contact our sales people you can get video of our reference running machine

Q2: Do you have agent and after-service stations?

A2: So far we have agent in Iran,Nigeria,Dubai,Kenya, Bangladesh,Algeria,Pakistan welcome to join us!

Q3: Do you provide customized service

A3: We can design the machines according your requirements(materil ,power,the kinds of the pen sample,and so on),at the same time we

will give you our professional suggestion,as you know,we have been in this industry for many years.

Q4: What's your guarantee or the warranty of the quality if we buy your machines?

A4: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q5: How long time for installation?

A5: According your machines order,we will send one or two engineers to your plant,it will take about 10 days to 25 days.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Kevin Dong

Phone: +86 135 8442 7912

E-mail: info@bemachine.cn

Whatsapp:8613584427912

Add: Jiangsu Province,Zhangjiagang City, Leyu Development Zone,