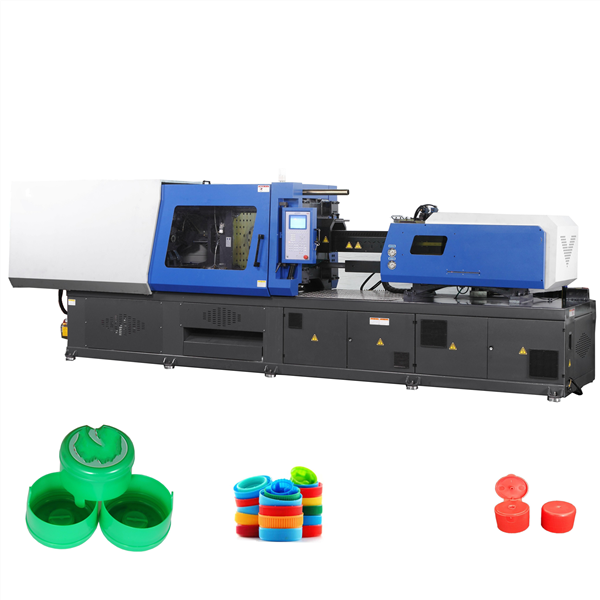

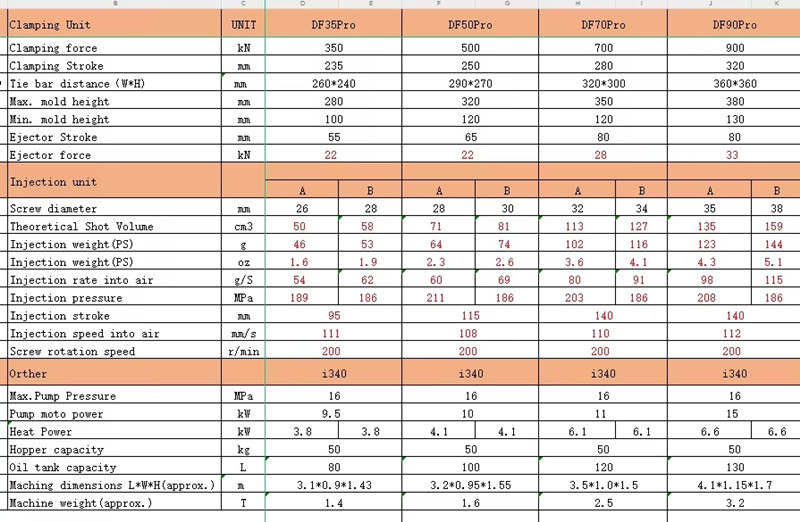

90 Ton Injection Moulding Machine

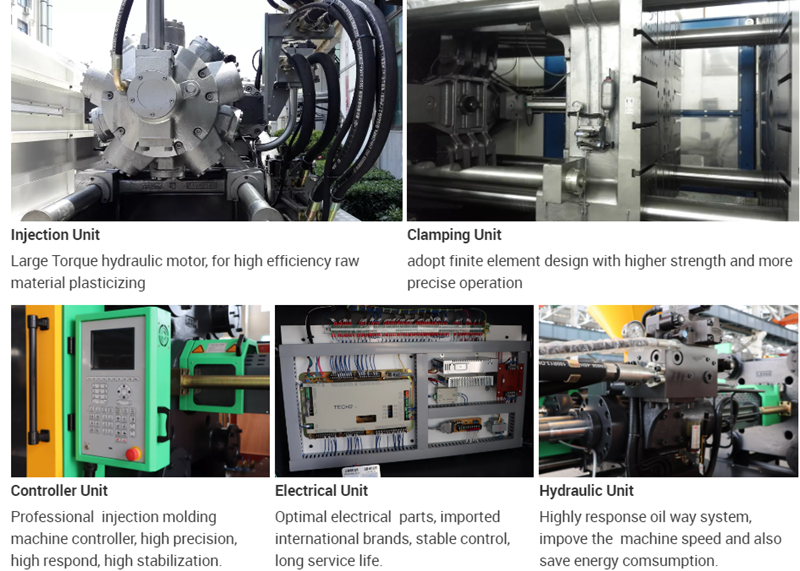

Plastic Injection Moulding Machine.Adopting Europe technology,hydraulic unit adopts proportional pressure and flow control,the pressure and the speed can be adjusted,stable movement curve and gentle shock,the computer is imported from Industry family. The LCD displaying screen with high clarity has Chinese and English language to use. Close-loop PID temperature control with the advantage of high precision. The operating table of the injection moulding machine have two safety, one is machine safety, another is electrical safety, that ensures the operators’s safety.

90 Ton Injection Moulding Machine

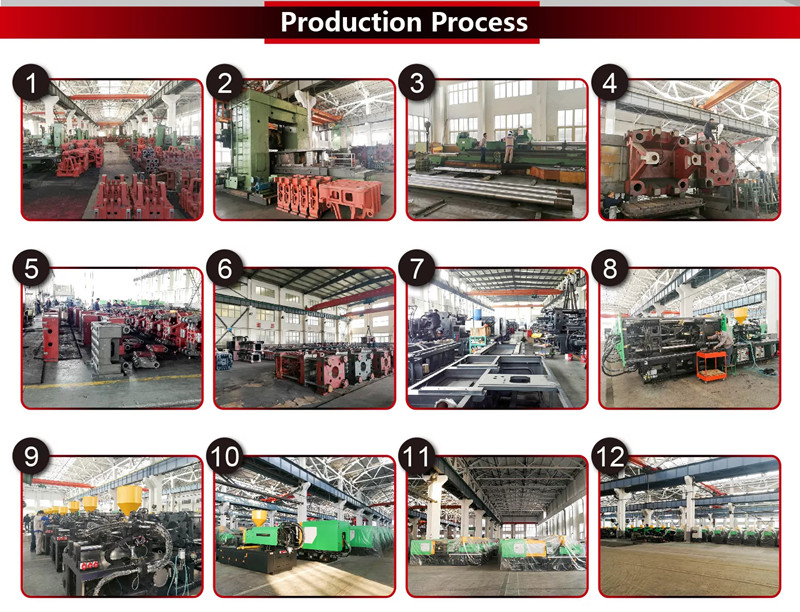

Machine Features:

1) Precision hydraulic synchronous template adjusting system

2) Optimal design of high-strength precision clamping structure, Clamping unit rigidity and accuracy

3) Large colorful screen high-precision computer system, precision control, easily operation, multi operation language available.

High-precision displacement sensor system, temperature control accuracy, big capacity data storage and date protection ability

4) World famous brand electrical system

5) Balanced type of double injection cylinder, eliminate oblique torque, diminishes deformation of screw and barrel, extend life of screw

and barrel, optimizes plasticizing effect. Machine injection under multi-pressure and at various speed, with big capacity hydraulic motor.

6) Large torque oil motor

7) Highly abrasion resistant alloy sliding block

8) The integrate type oil detachable oil tank, magnetic filter and bypass strainer. Reasonable and highly efficient lubrication system.

Modularized energy conservation high response oil system

9) Highly precise transducer, multi-stage control of opening stroke, speed and position. Flexible tie bars nut eliminate fatigue fracture,

assure tie bars long working life.

10) Security door fitted with hydraulic, mechanical and electrical interlocking triple safety device, fully protect machine operator.

11) Energy saving system, no extra energy consumption due to output volume changes according to load alteration. During stage of

holding pressure, servo motor lower down energy consumption, 0 energy consumption during machine cooling stage, save 20%-80%

energy consumption compare with standard machine.

Packing & Delivery

What the Injection Moulding Machine Can do?

For making Electronics, mobile phones, computers, household appliances and toys.

Liquid silicone products, such as pacifiers, bottles and precision seals.

Disposable lunch boxes, tableware and food packaging products.

Factory turnover box, family storage box, fruit packaging basket, etc.

PET bottle embryo, PP health care bottle, etc.

Automobile bumper, instrument panel, lamp and interior parts, etc.

LED industry bubble injection and plastic coated aluminum special.

Two-tone and mixed two-tone plastic products and other plastic products.

FAQ

Q: Are you a trading company or a manufacturer? A: Yes, we are factory, all the machines are made by ourselves,

we can provide customized service according to your requirements.

Q: Can you guarantee your quality? A: Absolutely. We are a manufacturing factory. What's more, we place our

reputation in high regard. The best quality has always been our principle. You can fully guarantee our production.

Q: What should we do if we receive the machine and it cannot be operated? A: The operating manual and video

demo are sent together with the machine to give instructions. In addition, we have a professional after-sales service

team to solve any problems at the customer's site.

Q: How can I get the spare parts on the machine? A: We will send extra fragile spare parts and accessories etc.

Non-man-made damaged spare parts will be sent free of charge and free shipping during the 1-year warranty period.

Q: Is there any installation direction after we receive the machine? Yes, we have a professional technical team and

enthusiastic after-sales service. We will solve any problems you encounter during the installation and packaging

production process in a timely manner.

Q: Is there any guarantee that can guarantee me to order from your company? A: We are Alibaba's on-site inspection

factory, quality, delivery time, your payment are all guaranteed by Alibaba Trade Assurance. This machine will have a

two-year warranty. During the warranty period, if any part is not man-made. We will replace it with a new one for you

free of charge. The warranty will start after the machine is issued. We receive the bill of lading.

Pre-sale service:

Provide professional technical support.

2. Send the product catalog and instruction manual.

3. If you have any questions, please contact us online or send us an email, we guarantee that we will reply you at the first time!

4. Personal calls or visits are warmly welcomed.

Service Sales:

We promise to be honest and fair and are happy to serve you as your sourcing consultant.

2. We guarantee punctuality, quality and quantity and strictly implement the terms of the contract.

After-sales service:

Where to buy our products 1 year warranty and lifetime maintenance.

24-hour telephone service.

Large stock of parts, easy to wear parts.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Kevin Dong

Phone: +86 135 8442 7912

E-mail: info@bemachine.cn

Whatsapp:8613584427912

Add: Jiangsu Province,Zhangjiagang City, Leyu Development Zone,