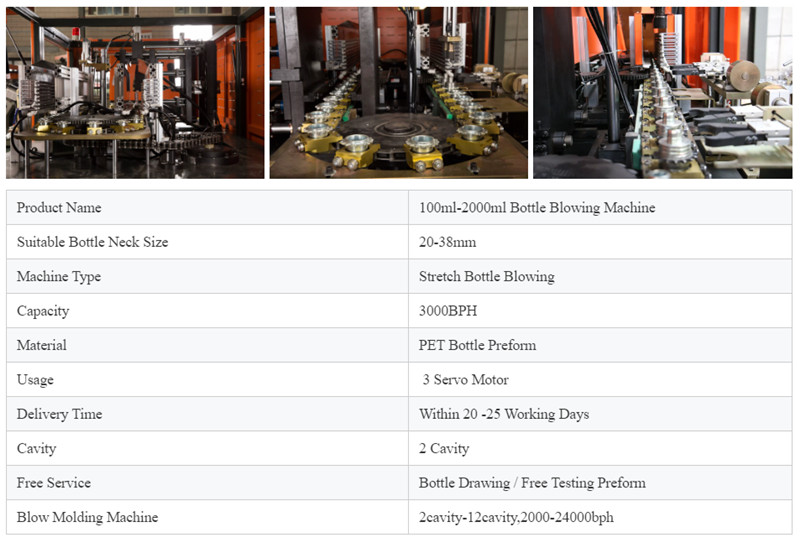

0.5L-2L Pet Bottle Automatic Blowing Machine 2 cavity

Full-automatic PET bottle blow molding machine is the most stable two-step automatic stretch blow moulding machine.PET bottle blowing machine has two cavities to six cavities and the maximum volume of the products is 2000ml. the speed is 3000 bottles per hour per cavity (based on 500ml bottle). PET bottle machine can blow bottles in shapes: carbonated, mineral, pesticide, cosmetics, wide-mouth, hot filling, and other packing containers, which is made of plastic of crystalline type, such as PET and PP etc.

0.5L-2L Pet Bottle Automatic Blowing Machine 2 cavity

production Introduction:

1). Stable performance with advanced PLC.

2). Automatic preform conveyer to save human cost.

3). Preform self-rotation and infrared pre-heater revolution assure the even distribution of heat, which improve the bottle shaping rate, increase the production.

4). High adjusting performance to enable preheat the preforms perfectly by adjust the voltage control area in the PLC, which could adjust the temperature of the infrared lights in the pre-heater, and keep the proper temperature and humidity invariable.

5). High safeties with security automatic-locking device in each mechanical action, which will make the production into a perfect safe environment, in case of the breakdown in certain procedure.

6). Introduce the FESTO air cylinder to avoid contamination and noise.

7). Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

8). Strong clamping force with high pressure and double crank links to lock the mould.

9). Two ways of operating: automatic and manual.

10). Safe\reliable and unique design of the position of valve to make the pneumatic diagram in the machine easier to understand.

11). Low cost\high efficiency\easy operation and maintenance etc, profited from the fully automatic technological process.

12). Ideal cooling system make the finished bottles without any flaws.

13). Easy for you to install\test and start up.

14). Low rejection rate: less than 0.2 percent.

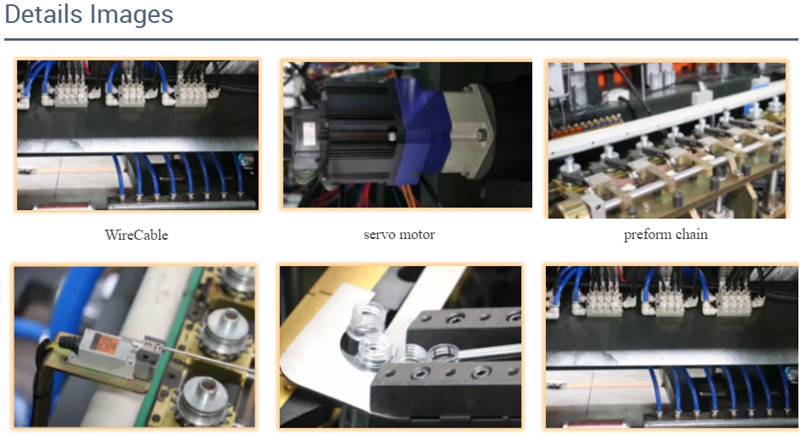

Main Techniacl Specifications:

Technique Parameter of blow molding machine:

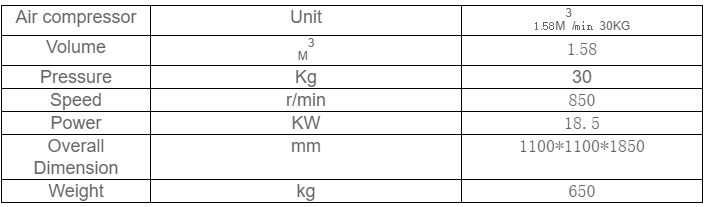

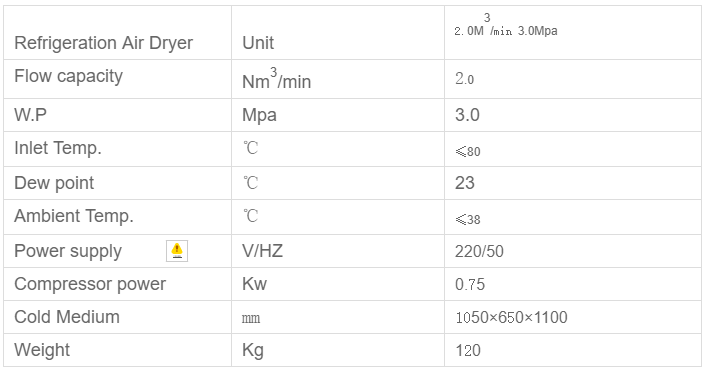

Functions of auxiliary equipments:

(1) Air compressor is the air source for PET stretch blow molding machine, carrying out the process of compressing air from atmosphere to the required pressure.

(2) Air dryer is to remove the moisture from the compressed air and lower temperature of the compressed air in the heat exchanger.

(3) Air filter is to clear up the impurities out of the compressed air, like carbon-hydrogen, tiny dust and solid particles.

(4) Air tank is to receive and supply air for the machine as storage.

HP air compressor:

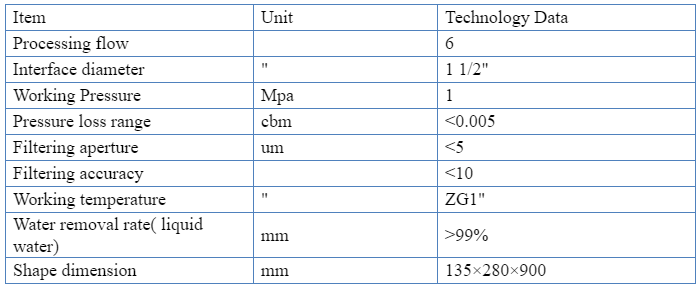

Air Cooling Drier:

Packing &Delivery

1. Automatic PET blowing machine packed by wooden case.

2. The delivery date of pet bottle blowing machine is within 45 days after payment.

![]()

![]()

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Kevin Dong

Phone: +86 135 8442 7912

E-mail: info@bemachine.cn

Whatsapp:8613584427912

Add: Jiangsu Province,Zhangjiagang City, Leyu Development Zone,